Warehouse Trends and Solutions for 2026: A Buyer's Guide for Irish Businesses

Warehouse operations in 2026 are defined by a convergence of automation, sustainability pressures and the ongoing challenge of maximising storage capacity within existing footprints. For Irish businesses managing warehouses, distribution centres or manufacturing facilities, understanding these trends is essential for making informed investment decisions.

This buyer's guide examines the key warehouse trends shaping 2026 and connects each to practical storage solutions available today. Whether you're planning a major facility upgrade or looking for incremental improvements, you'll find actionable guidance for optimising your operations.

The State of Warehousing in 2026

The warehousing landscape has shifted dramatically. E-commerce growth continues to drive demand for faster fulfilment, labour shortages persist across the logistics sector, and sustainability requirements have moved from optional to mandatory for many businesses

Key drivers shaping warehouse investment decisions:

- Space constraints: Urban land costs make expansion prohibitively expensive for many Irish businesses

- Labour challenges: Difficulty attracting and retaining warehouse staff pushes adoption of efficiency-improving solutions

- Customer expectations: Same-day and next-day delivery requirements demand streamlined operations

- Sustainability mandates: ESG reporting and carbon reduction targets influence procurement decisions

- Technology integration: Software-defined warehouse management becomes standard practice

Against this backdrop, the smartest investments focus on solutions that address multiple challenges simultaneously: maximising existing space, improving worker productivity and safety, and supporting operational flexibility.

Trend 1: Vertical Storage Maximisation

Why it matters in 2026: With warehouse space at a premium across Ireland, businesses are looking upward rather than outward. Vertical storage strategies can significantly increase capacity without requiring building footprint expansion.

The shift toward high-density vertical storage reflects a fundamental change in how warehouse managers think about space. Rather than measuring efficiency by square metres alone, forward-thinking operations now consider cubic metres: the total volumetric capacity of their facilities.

Practical solutions:

Pallet racking systems remain the foundation of vertical storage strategy. Modern pallet racking configurations can reach heights of 10 metres or more, transforming single-level storage areas into multi-tier inventory systems. The key is matching racking type to your operational requirements:

- Selective racking provides direct access to every pallet, ideal for operations with diverse SKUs

- Double-deep racking increases density by storing pallets two deep, trading some selectivity for 50% more capacity

- Drive-in racking maximises density for high-volume, low-SKU operations

Industrial pallet racking from suppliers like Kimer (exclusively distributed by RackZone in Ireland) offers load capacities up to 3,500kg per level with ISO 9001 compliance, ensuring both capacity and safety standards are met.

Buyer's checklist for vertical storage:

[ ] Assess current ceiling height utilisation

[ ] Evaluate forklift reach capabilities

[ ] Review floor load-bearing capacity

[ ] Consider lighting and sprinkler system clearances

[ ] Calculate cost per pallet position across different configurations

Trend 2: Flexible and Modular Storage Systems

Why it matters in 2026: Business conditions change rapidly. Storage systems that can adapt without complete replacement protect your investment and support operational agility.

The demand for flexibility drives increased adoption of modular storage solutions. Longspan racking exemplifies this approach: screwless assembly allows reconfiguration in minutes, starter and extender units connect seamlessly, and the system expands incrementally as needs grow.

Key characteristics of flexible storage:

- Adjustable beam heights accommodate changing product dimensions

- Modular components enable expansion without replacing existing infrastructure

- Quick assembly reduces installation downtime

- Compatibility with accessories and add-ons extends functionality

Longspan shelving handles loads up to 450kg per timber shelf and assembles in 10-15 minutes per bay. This makes it particularly valuable for businesses experiencing growth or seasonal fluctuations, as capacity can be added rapidly without the need for specialist installation.

Applications across industries:

- E-commerce fulfilment: Rapidly adjustable pick faces for changing product lines

- Manufacturing: Flexible work-in-progress storage that adapts to production schedules

- Retail distribution: Seasonal capacity expansion for peak trading periods

- Third-party logistics: Reconfigurable storage zones for different client requirements

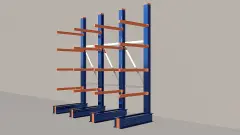

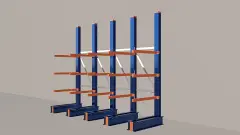

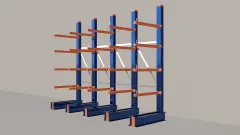

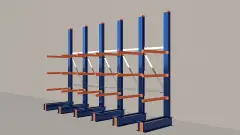

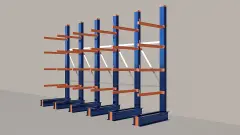

Trend 3: Specialised Storage for Irregular Items

Why it matters in 2026: Standard pallet racking doesn't suit every product. Businesses handling timber, pipes, sheet materials or other long goods need purpose-built solutions to maximise space and ensure safe handling.

Cantilever racking addresses this need with horizontal arms extending from vertical uprights, providing unobstructed access for loading and unloading lengthy materials. The absence of front columns means forklifts can approach from either side, dramatically improving handling efficiency.

Industries benefiting from cantilever systems:

- Timber yards and builders' merchants

- Steel and metal distributors

- Furniture manufacturers

- Automotive suppliers

- Textile mills handling fabric rolls

Kimer cantilever racking features adjustable arms that can be repositioned or added as storage requirements change. Constructed from S-355 quality steel, these systems meet EN ISO 9001 safety standards and withstand demanding warehouse conditions.

Configuration options:

- Single-sided units position against walls, maximising floor space

- Double-sided units provide access from both sides, ideal for central locations

- Light, medium and heavy-duty options match load requirements

Trend 4: Worker Safety and Ergonomics

Why it matters in 2026: Labour shortages mean retaining existing staff is as important as recruiting new workers. Investments in safety and ergonomics reduce injuries, improve productivity and make warehouse roles more attractive.

This trend manifests across multiple solution categories:

Racking protection prevents costly damage from forklift impacts. Pallet racking accessories, including upright protectors, frame guards and corner protectors, absorb impacts that would otherwise weaken structural components. Given that forklift collisions can compromise load-bearing capacity and create serious safety hazards, protection accessories offer a significant return on investment.

Safe access equipment enables workers to reach elevated storage safely. Mobile safety steps with locking mechanisms, handrails and non-slip treads replace improvised solutions like standing on pallets or climbing racking. Industrial mobile steps range from 2-tread units to 8-tread platforms reaching 2,000mm, with narrow aisle options (600mm width) for space-constrained environments.

Anti-fatigue flooring addresses the physical toll of standing on concrete. Interlocking floor mats create ergonomic surfaces at packing stations, assembly areas and other locations where workers stand for extended periods. These mats reduce muscle fatigue and joint strain, improving both comfort and productivity.

Material handling equipment minimises manual lifting. Platform trolleys with capacities from 50kg to 700kg, pallet trucks and hand trucks reduce physical strain and speed up internal transport.

Trend 5: Small Parts Organisation and Picking Efficiency

Why it matters in 2026: Order accuracy and picking speed have a direct impact on customer satisfaction and operational costs. Disorganised small parts storage creates bottlenecks that ripple through entire fulfilment processes.

Efficient small parts storage combines visibility, accessibility and systematic organisation:

Parts bins provide stackable, labelable storage for screws, bolts, components and other small items. Available in multiple colours and sizes, they integrate with standard shelving systems to create organised pick faces.

Tilt bins offer angled access with 45-degree tilting mechanisms. Transparent front panels allow instant content identification, and optional locking bars secure bins during transport. These systems mount on walls, workbenches or freestanding frames.

Louvre panels transform wall space into functional storage. These powder-coated steel panels accept compatible bins at various heights and configurations, keeping components within reach while freeing floor space.

Bin racks combine shelving frames with multiple bin positions. Mobile versions with caster wheels bring storage to the work area, reducing walking time in large facilities.

Impact on operations:

- Reduced picking errors through clear visual identification

- Faster order assembly with logical item positioning

- Lower training time for new staff navigating organised systems

- Better inventory control with systematic storage locations

Trend 6: Sustainability Through Storage Efficiency

Why it matters in 2026: Sustainability has moved from corporate aspiration to operational requirement. Storage decisions directly impact energy consumption, material usage and waste generation.

Efficient storage contributes to sustainability goals in several ways:

Maximising existing space eliminates the need for new construction. High-density systems like double-deep racking or vertical storage reduce the carbon footprint associated with building additional warehouse capacity. Every cubic metre of effective storage gained is a construction avoided.

Durable equipment reduces replacement frequency. Powder-coated steel industrial shelving and S-355 quality steel racking systems last for decades with proper maintenance, minimising material consumption over time.

Reusable containers replace single-use packaging. Euro containers and attached lid containers facilitate internal logistics without cardboard waste. These stackable, cleanable containers suit repeated use across supply chain movements.

Energy-efficient layouts reduce forklift travel and lighting requirements. Well-designed racking configurations minimise aisle width while maintaining safe access, concentrating inventory and reducing the heated/lit area required.

Questions to evaluate sustainability impact:

- How much additional capacity can be created within existing walls?

- What is the expected lifespan of the proposed storage equipment?

- Can reusable containers replace disposable packaging in internal movements?

- Does the layout minimise energy consumption for lighting, heating and equipment operation?

Trend 7: Integration of Workstations with Storage

Why it matters in 2026: Disconnected storage and work areas create inefficiency. Integrated solutions that combine benching with organisational systems streamline workflows.

Industrial workbenches now function as complete work cells rather than simple surfaces. Modern configurations include:

- Integrated storage shelves above and below work surfaces

- Pegboard backing for tool organisation

- Hanging rails for frequently accessed items

- Reel bars for packaging materials

Standard dimensions accommodate various applications, with widths from 1,500mm to 1,850mm and adjustable heights to suit different tasks. Mobile versions with caster wheels (two with brakes for stability) relocate as production requirements change.

For operations combining storage with assembly or packing, longspan shelving with built-in workbench configurations spans up to 7.5 metres, creating integrated work zones within storage areas.

Trend 8: Wire Mesh Decking for Safety and Compliance

Why it matters in 2026: Fire safety regulations and insurance requirements increasingly specify open-structure decking that allows sprinkler penetration. Wire mesh solutions address compliance while improving operational visibility.

Wire mesh decking installs on pallet racking beams to create solid, ventilated shelf surfaces. Benefits include:

- Fire safety compliance: Open mesh allows sprinkler water distribution

- Improved visibility: See through to levels above and below

- Versatile storage: Accommodates non-palletised items, boxes and irregularly shaped goods

- Debris containment: Prevents items from falling through beam gaps

Heavy-duty options support up to 1,000kg per panel depending on the conditions/temperature. Custom sizing ensures proper fit with existing racking configurations.

Trend 9: Preparing for Future Automation

Why it matters in 2026: Even businesses not ready for full automation should consider future compatibility when selecting storage infrastructure. Racking systems installed today may need to support autonomous equipment within their service life.

Compatibility considerations:

- Consistent dimensions across racking bays facilitate automated navigation

- Clear floor markings and protected uprights support future AMR (autonomous mobile robot) deployment

- Standardised container sizes enable automated handling

- Digital-ready layouts with logical addressing systems integrate with warehouse management software

Euro containers with standardised dimensions (compliant with Euro pallet footprints) represent an example of future-ready investment. These containers integrate with conveyor systems, automated storage/retrieval systems and robotic handling equipment.

Making the Right Investment Decision

Selecting warehouse storage solutions requires striking a balance between immediate needs and long-term flexibility. Consider these factors:

Current pain points:

- Are you running out of space?

- Is picking accuracy or speed inadequate?

- Do safety incidents or near-misses indicate equipment deficiencies?

- Is worker retention affected by physical working conditions?

Growth trajectory:

- What capacity will you need in 3-5 years?

- Are product dimensions or weights likely to change?

- Will fulfilment requirements become more demanding?

Budget structure:

- Is capital expenditure or operational expenditure preferred?

- What payback period is acceptable?

- Are there seasonal cash flow considerations?

Installation constraints:

- Can installation happen during normal operations?

- What downtime is acceptable?

- Are specialist installers required?

Partner with RackZone for 2026 and Beyond

RackZone is Ireland's leading supplier of pallet racking, industrial shelving and warehouse storage solutions. As the sole Irish distributor of Kimer products (with over 50 years of storage system expertise), RackZone combines international engineering excellence with local service and support.

Why Irish businesses choose RackZone:

- Comprehensive range: From parts bins to heavy-duty pallet racking, one supplier covers all requirements

- Stock in Ireland: Next business day delivery on orders before 3 pm

- Expert guidance: Trained team available by phone to discuss specific requirements

- Professional installation: End-to-end warehouse fitout services available

- Proven track record: Excellent Trustpilot rating, 100% Irish-owned

Ready to optimise your warehouse for 2026? Call +353 (0)90 9673261 to discuss your requirements with the RackZone team, or browse the full range at rackzone.ie.

Frequently Asked Questions

What is the most cost-effective way to increase warehouse storage capacity?

Are modular storage systems suitable for growing businesses?

How do I choose between different pallet racking configurations?

What safety equipment should every warehouse have?

How can storage solutions support sustainability goals?

"Always good range of storage products and great service with fast delivery. We have first bought from Rackzone almost 8 years ago and every transaction to date same been first class. Prices are competive. Highly Recomended Irish Company."

Jason Elliot

"Excellent company to deal with. High quality product with a very efficient delivery service. Very easy to assemble. Excellent customer service. Would highly recommend."

Nick Roche

Value Shelving

Value Shelving  Warehouse Shelving

Warehouse Shelving Industrial Shelving

Industrial Shelving Garage Shelving

Garage Shelving Metal Shelving

Metal Shelving  Plastic Shelving

Plastic Shelving HORECA

HORECA Galvanised Shelving

Galvanised Shelving

Industrial Workbench

Industrial Workbench  Value Workbench

Value Workbench  Modular Workstations

Modular Workstations

Matting

Matting  Metal Lockers & Benches

Metal Lockers & Benches Office

Office  Slatwall

Slatwall  Cabinets

Cabinets Plastic Lockers

Plastic Lockers Lean Products

Lean Products Mobile Steps

Mobile Steps Wall-Zone

Wall-Zone

Longspan Racking

Longspan Racking  Cantilever Racking

Cantilever Racking  Industrial Pallet Racking

Industrial Pallet Racking Wire Mesh Decking

Wire Mesh Decking Tyre Racking

Tyre Racking Vertical Storage

Vertical Storage Racking Accessories

Racking Accessories Up & Over Gates

Up & Over Gates

Containers & Boxes

Containers & Boxes  Louvre Panels

Louvre Panels Crystal Box Systems

Crystal Box Systems Parts Bins

Parts Bins  Euro Containers

Euro Containers Visible Storage Boxes

Visible Storage Boxes  Foldable Crates

Foldable Crates

Shelf Bin

Shelf Bin Tool Organiser

Tool Organiser

Waste Management

Waste Management Cabinets

Cabinets Chemical & CoSHH Cabinets

Chemical & CoSHH Cabinets  Hex Lighting

Hex Lighting Packaging

Packaging

Platform Trolleys

Platform Trolleys  Hand Trucks

Hand Trucks  Pallet Trucks

Pallet Trucks  Plastic Pallets

Plastic Pallets