EN 15635: What It Is & What You Need to Know

Key Takeaways:

- EN-15635 is a European standard that establishes safety and performance requirements for static storage systems, including pallet racking and industrial shelving.

- The standard matters for Irish warehouses because it prevents catastrophic storage system failures and demonstrates due diligence during Health and Safety Authority inspections.

- Design and construction requirements mandate rigorous structural specifications and manufacturing quality standards for warehouse racking compliance.

- Comprehensive testing protocols verify load capacities and connection system reliability under real-world operating conditions.

- Clear marking, labelling, and capacity identification requirements are mandatory on every storage bay.Regular inspection protocols include daily visual checks, monthly detailed inspections, and annual professional assessments.

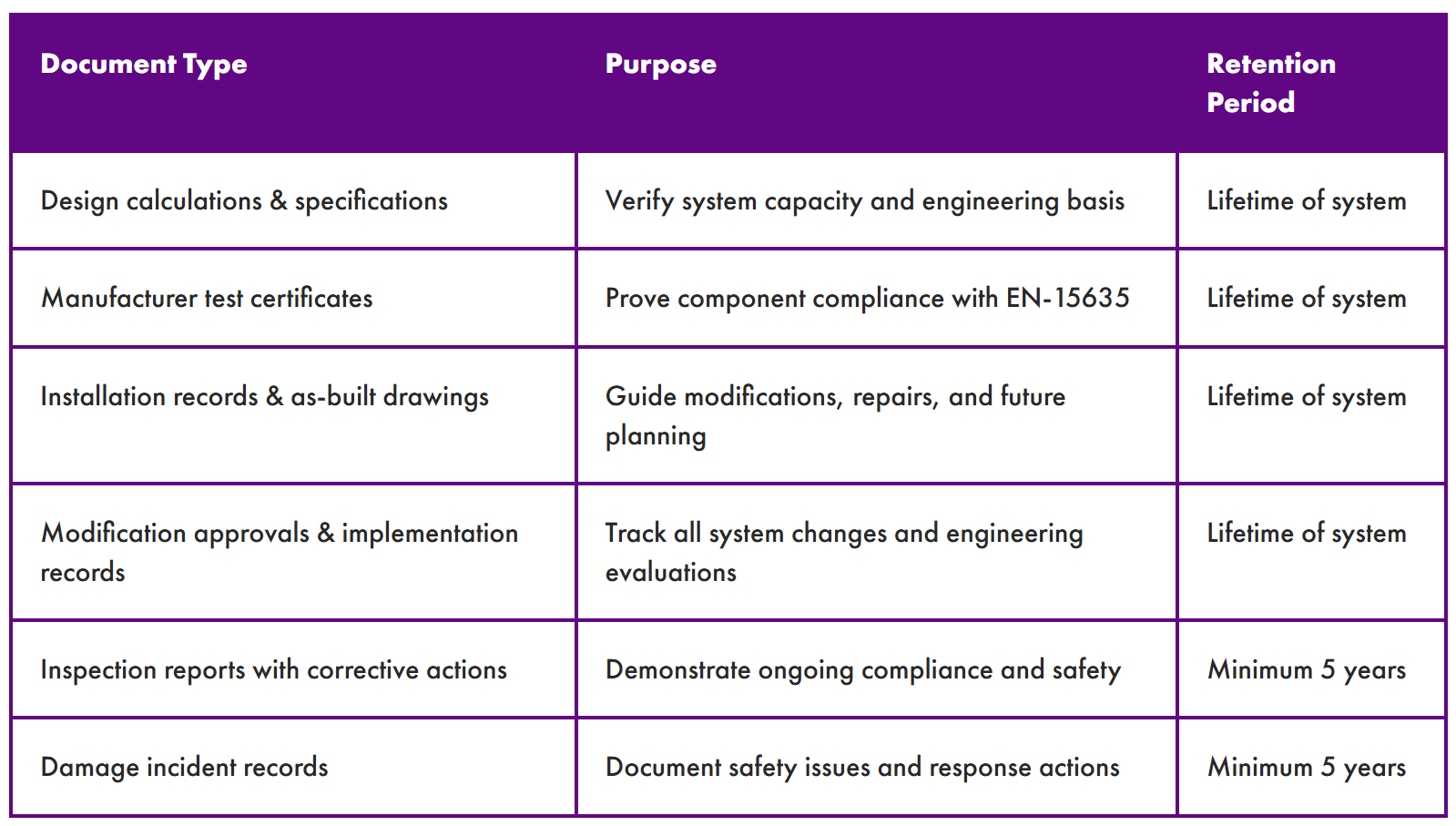

- Comprehensive documentation and modification control systems must be maintained throughout the system's operational life.

- Implementing EN-15635 requires initial compliance assessment and ongoing management programs.

The European standard EN-15635 establishes safety and performance requirements for static storage systems, including pallet racking and industrial shelving. This pallet racking safety standard provides comprehensive specifications covering design, construction, testing, installation, maintenance and documentation requirements that ensure storage systems operate safely under intended load conditions throughout their operational lifecycle.

Why Does EN-15635 Matter for Irish Warehouses?

Storage system failures create catastrophic consequences. Collapsed racks injure workers, destroy inventory worth thousands, disrupt operations for days, and generate liability exposures requiring extensive legal defence. EN-15635 certification prevents these scenarios through systematic warehouse safety regulations addressing every critical aspect of storage system performance.

Irish businesses operating warehouses, distribution centres, manufacturing facilities, and retail stockrooms must understand EN-15635 racking compliance requirements. The standard doesn't mandate legal compliance in all situations, but demonstrates due diligence during Health and Safety Authority inspections. Insurance providers frequently require EN-15635 compliance documentation, with non-compliant facilities facing coverage restrictions or premium increases.

Implementation transforms operational reliability through systematic safety requirements. Systematic testing protocols catch design flaws before installation. Regular storage system inspection requirements preserve structural integrity. Documentation standards create accountability throughout system lifecycles.

What Are the Design and Construction Requirements Under EN-15635?

Structural Specifications

EN-15635 mandates rigorous design standards for warehouse shelving and racking systems. Engineers must calculate:

- Load capacities for maximum intended weights

- Dynamic forces during loading operations

- Seismic considerations for geographic locations

- Safety factors to prevent overload failures

- Minimum yield strengths

- Thickness tolerances

- Weld quality standards

- Documented racking load capacity ratings for connection systems

Frame geometry must maintain stability under maximum loading scenarios without excessive deflection. Design documentation includes engineering drawings specifying all dimensions, material grades, component capacities, and assembly requirements. Manufacturers provide these specifications, enabling proper system selection, installation verification and future modification planning.

Manufacturing Quality Standards

Production processes require quality control protocols verifying that components meet design specifications:

- Dimensional checks ensure uprights, beams and connections maintain specified tolerances

- Material testing confirms steel grades match engineering requirements

- Weld inspections verify joint strength and integrity

- Visual examination identifies surface damage, coating defects or manufacturing anomalies

- Load testing on sample components validates capacity ratings

Finished component inspection catches defects before shipping, ensuring dimensional verification and proper component fit during installation.

What Testing Protocols Does EN-15635 Require?

Load Testing Requirements

The standard specifies comprehensive load testing protocols simulating real-world operating conditions:

- Static load tests: Verify systems withstand maximum rated capacities without failure or excessive deformation

- Progressive loading sequences: Establish capacity limits and safety margins

- Dynamic testing: Simulates impact forces from forklift operations, pallet placement, and equipment movements

- Fatigue testing: Identifies potential failure modes developing over extended operational periods

Systems must maintain structural integrity under repeated loading cycles representing years of warehouse use. Test documentation records all procedures, results, and observations. Manufacturers maintain test certificates demonstrating compliance with EN-15635 requirements, verified during safety inspections and insurance audits.

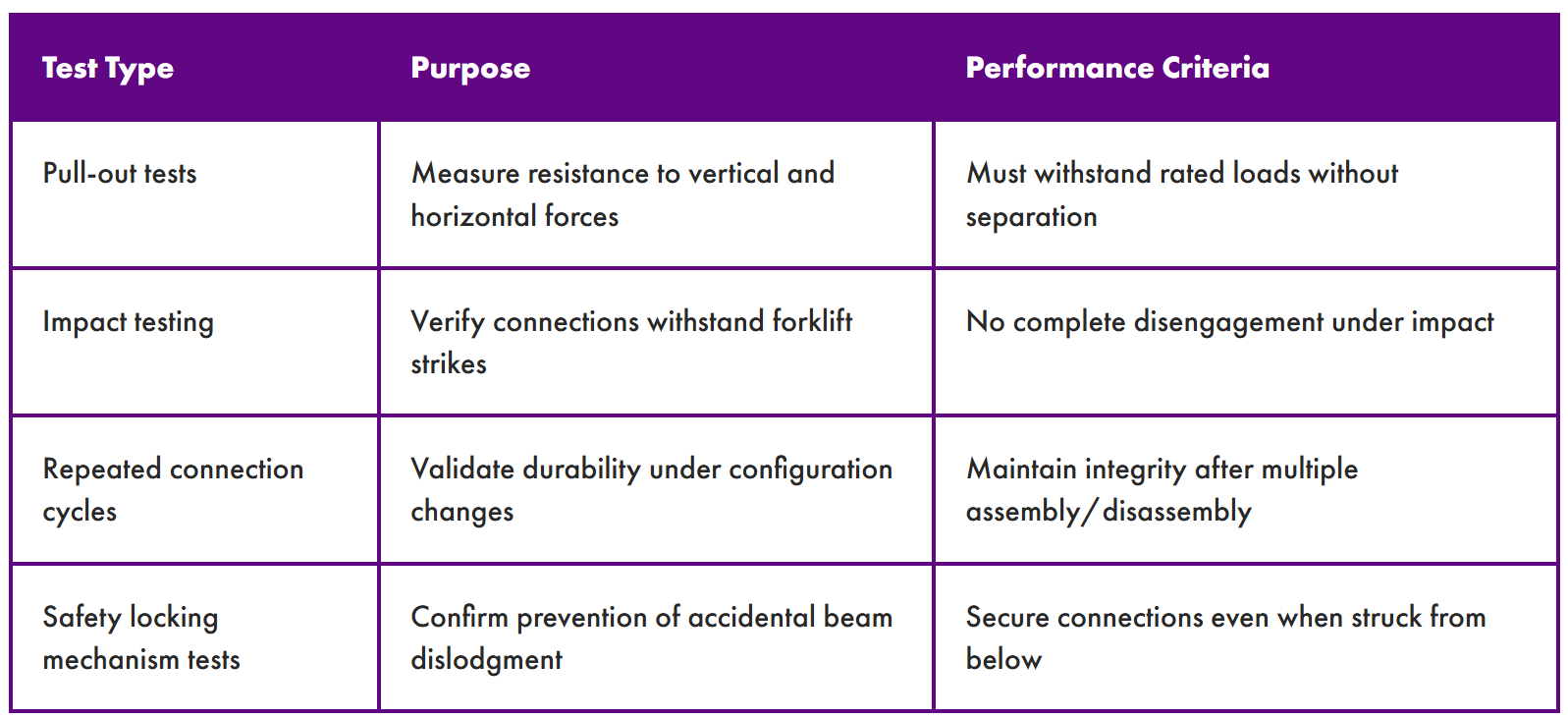

Connection System Verification

Beam-to-upright connections require specific testing protocols:

Documentation demonstrates connection reliability under various loading scenarios.

What Marking and Labelling Requirements Does EN-15635 Mandate?

Capacity Identification

EN-15635 mandates clear load capacity information displayed on every storage bay:

- Maximum weights per beam level

- Total bay capacity

- Maximum pallet dimensions

- Information must remain visible and legible throughout operational life

Capacity plates require specific content:

- Manufacturer identification

- System type designation

- Design load ratings

- Installation date

- Relevant standard compliance

Durable materials withstand warehouse environments without fading or damage. Strategic placement ensures operators see capacity limits before loading pallets.

Warning labels highlight critical safety information:

- Areas requiring personal protective equipment

- Forklift operation restrictions

- Climbing prohibitions

- Modification restrictions

- Standardised symbols ensure comprehension across language barriers

Comprehensive installation records demonstrate proper system implementation:

- As-built drawings showing actual layout

- Floor anchoring locations and specifications

- Component serial numbers and manufacturing dates

- Installer certifications

- Load testing results

This documentation supports future modifications, guides maintenance activities, provides evidence during inspections and facilitates damage assessment after incidents. Facilities must maintain accessible records throughout the system's operational life.

What Maintenance and Inspection Requirements Are Specified in EN-15635?

Regular Inspection Protocols

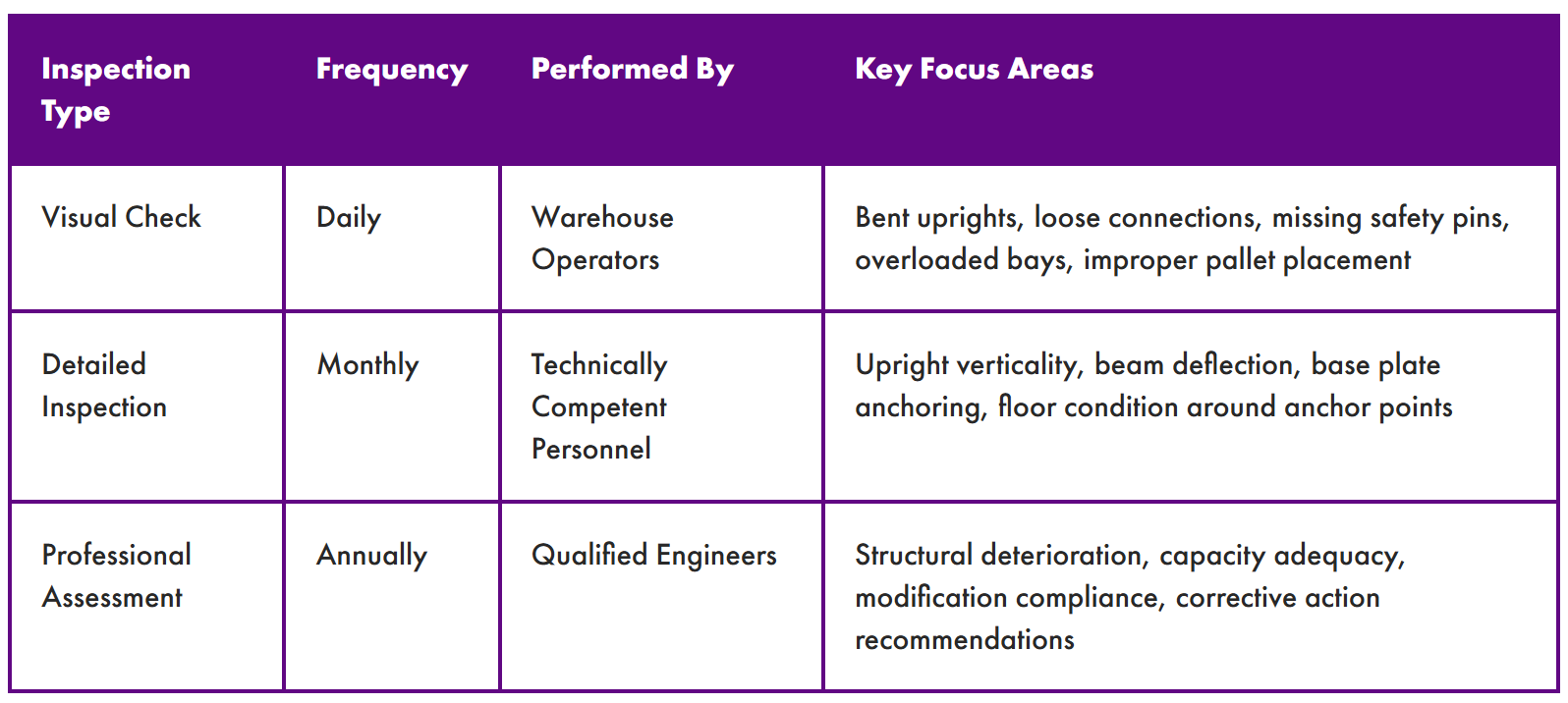

EN-15635 specifies systematic storage system inspection requirements for maintaining warehouse racking compliance:

Daily visual checks by warehouse operators identify obvious damage. Monthly detailed inspections examine structural components systematically using levels or laser alignment tools. Annual professional inspections by qualified engineers provide comprehensive expert evaluation, creating official records for regulatory compliance.

Damage Reporting and Repair

The standard requires immediate damage reporting systems:

- Operators must notify supervisors of any rack damage, no matter how minor

- Damaged components need assessment by competent persons to determine repair or replacement requirements

- Temporary repairs aren't acceptable for load-bearing elements

- Damaged uprights, beams, or connections require proper replacement using manufacturer-approved components

- Load capacity reductions apply to damaged areas until permanent repairs are completed

- Documentation tracks all damage incidents, assessments and corrective actions

What Documentation Must Be Maintained for EN-15635 Compliance?

Required System Documentation

Facilities must maintain comprehensive documentation throughout the storage system's operational life:

Organised filing systems ensure document accessibility. Digital copies provide backup protection against physical document loss. Regular reviews verify documentation completeness and currency. These records demonstrate compliance during audits and provide critical information during emergencies.

Modification Control

EN-15635 prohibits unauthorised system modifications. Any changes to configuration, loading patterns, or component specifications require:

- Engineering evaluation and design calculations confirming safety under new conditions

- Manufacturer approval for component changes

- Updated capacity labelling reflecting modified ratings

- Comprehensive documentation creating audit trails

Documentation tracks all modifications, including engineering approvals, implementation dates, updated drawings, and revised capacity information, demonstrating ongoing compliance with pallet racking safety standards.

How Do You Implement EN-15635 in Your Facility?

Initial Compliance Assessment

Evaluate existing storage systems against EN-15635 requirements:

1. Review available documentation identifying gaps in records

2. Conduct physical inspections assessing current system condition

3. Compare operational practices against standard requirements

4. Identify compliance gaps requiring corrective action

Prioritise issues based on safety criticality:

- Immediate hazards: Need emergency response

- Structural concerns: Require prompt engineering evaluation

- Documentation deficiencies: Allow scheduled completion

- Operational procedure gaps: Need training implementation

Establish systematic programs maintaining EN-15635 compliance:

- Implement inspection schedules covering daily, monthly, and annual requirements

- Create damage reporting systems ensuring immediate notification

- Develop documentation procedures capturing all required records

- Train personnel on their compliance responsibilities

- Track incident trends identifying recurring problems

- Monitor inspection completion rates

- Audit documentation systems for completeness

- Implement continuous improvement processes addressing identified deficiencies

Regular program reviews verify effectiveness and maintain warehouse safety regulations compliance.

How Can Storage System Experts Help with EN-15635 Compliance?

EN-15635 compliance requires technical expertise beyond typical warehouse management capabilities. Professional support ensures:

- Proper implementation of safety standards

- Documentation accuracy for regulatory compliance

- Ongoing compliance maintenance programs

- Regulatory confidence during inspections

RackZone supplies storage systems designed to EN-15635 standards. Our pallet racking accessories enhance system safety and functionality. From wire mesh decking preventing pallet collapse to corner protectors defending against impact damage, we provide components supporting compliant operations.

Our technical team provides:

- Guidance on proper system selection for your warehouse racking compliance needs

- Installation support ensuring standards are met

- Documentation supporting EN-15635 certification

- Maintenance protocol recommendations

- Next-business-day delivery across Ireland when you order before 3 pm

Explore our comprehensive storage and organisation solutions or contact our specialists for guidance on EN-15635 compliance. Call +353 (0)90 9673261 to discuss your facility's specific requirements and develop strategies ensuring safe, compliant warehouse operations.

Value Shelving

Value Shelving  Warehouse Shelving

Warehouse Shelving Industrial Shelving

Industrial Shelving Garage Shelving

Garage Shelving Metal Shelving

Metal Shelving  Plastic Shelving

Plastic Shelving HORECA

HORECA Galvanised Shelving

Galvanised Shelving

Industrial Workbench

Industrial Workbench  Value Workbench

Value Workbench  Modular Workstations

Modular Workstations

Matting

Matting  Metal Lockers & Benches

Metal Lockers & Benches Office

Office  Slatwall

Slatwall  Cabinets

Cabinets Plastic Lockers

Plastic Lockers Lean Products

Lean Products Mobile Steps

Mobile Steps Wall-Zone

Wall-Zone

Longspan Racking

Longspan Racking  Cantilever Racking

Cantilever Racking  Industrial Pallet Racking

Industrial Pallet Racking Wire Mesh Decking

Wire Mesh Decking Tyre Racking

Tyre Racking Vertical Storage

Vertical Storage Racking Accessories

Racking Accessories Up & Over Gates

Up & Over Gates

Containers & Boxes

Containers & Boxes  Louvre Panels

Louvre Panels Crystal Box Systems

Crystal Box Systems Parts Bins

Parts Bins  Euro Containers

Euro Containers Visible Storage Boxes

Visible Storage Boxes  Foldable Crates

Foldable Crates

Shelf Bin

Shelf Bin Tool Organiser

Tool Organiser

Waste Management

Waste Management Cabinets

Cabinets Chemical & CoSHH Cabinets

Chemical & CoSHH Cabinets  Hex Lighting

Hex Lighting Packaging

Packaging

Platform Trolleys

Platform Trolleys  Hand Trucks

Hand Trucks  Pallet Trucks

Pallet Trucks  Plastic Pallets

Plastic Pallets