A Guide to Pallet Racking

Estimated reading time: 12 minutes

Key Takeaways:

- Successful racking selection begins with thorough inventory analysis of dimensions, weights, quantities and handling requirements.

- Selective pallet racking provides direct access to every pallet, making it ideal for diverse SKU ranges requiring frequent product rotation.

- Cantilever racking solves storage challenges for long, bulky or irregularly shaped materials unsuitable for standard pallet configurations.

- Drive-in racking maximises storage density by eliminating aisles between rack rows, ideal for large quantities of identical products.

- Longspan shelving bridges the gap between light-duty shelving and heavy pallet racking for hand-loaded items.

- Narrow aisle systems reduce aisle widths to 1,600-1,800mm, increasing pallet positions by 40-50% within existing footprints.

- Mobile racking mounts entire rack structures on motorised bases, achieving 80-100% capacity increase compared to static selective racking.

- Push-back systems use nested carts on inclined rails, enabling pallet storage 2-6 deep with better selectivity than drive-in configurations.

- Wire mesh decking, racking accessories, and load capacity signage are essential accessories enhancing performance and safety.

- Professional installation ensures structural integrity, regulatory compliance and optimal performance.

- Compare suppliers systematically beyond pricing, evaluating quality, installation capabilities, warranty terms and long-term support.

- Design systems accommodating predictable growth through modular configurations and standardised components.

Selecting appropriate pallet racking determines warehouse efficiency, storage capacity and operational costs for years to come. The wrong warehouse storage solutions create bottlenecks, waste valuable floor space and require expensive reconfiguration. This comprehensive buyers' guide examines every critical factor influencing racking selection: inventory characteristics, access requirements, space constraints, budget parameters and future scalability needs, enabling informed decisions matching your specific operational requirements.

What Storage Requirements Should You Consider Before Buying Pallet Racking?

Successful racking selection begins with thorough inventory analysis. Document what you're storing: dimensions, weights, quantities and handling requirements. Measure pallet sizes precisely - standard Euro pallets (1200mm x 800mm) and UK pallets (1200mm x 1000mm) require different beam configurations. Non-standard dimensions need custom solutions.

Standard Pallet Sizes in Ireland

| Pallet Type | Dimensions (mm) | Typical Weight Capacity | Common Uses |

|---|---|---|---|

| Euro Pallet | 1200 x 800 | Up to 1,500kg | Standard European distribution |

| UK Pallet | 1200 x 1000 | Up to 1,000-1,500kg | UK market products |

| Custom | Varies | Varies | Specialised applications |

Note: Actual pallet weight capacities depend on pallet construction, load distribution and handling methods.

Calculate weight distributions across your inventory range. Heaviest items determine beam and upright specifications. Mixing heavy and light goods on the same system risks underutilising capacity or creating safety hazards through overloading lighter sections.

Assess inventory velocity: how frequently you access different products. Fast-moving goods require immediate accessibility. Slow-moving stock can occupy less accessible positions. Seasonal fluctuations affect space requirements - Christmas inventory surges, summer garden product peaks and back-to-school rushes create temporary capacity demands.

Project future growth realistically. Warehouses often reach high capacity utilisation within the first few years of installation. Factor expansion plans into initial specifications. Modular systems accommodate growth better than fixed configurations, though at a higher initial cost.

What is Selective Pallet Racking and When Should You Use It?

Selective pallet racking provides direct access to every pallet without moving others, making it ideal for diverse SKU ranges requiring frequent product rotation. This most common warehouse storage solution consists of upright frames and horizontal beams, creating organised storage lanes forklift operators navigate efficiently.

Key advantages:

- Immediate access to all inventory

- Simple FIFO (first-in, first-out) implementation

- Straightforward installation

- Easily adjustable beam heights

- Competitive pricing

- Compatible with standard forklifts

Selective systems suit operations prioritising accessibility over maximum density: retail distribution centres, mixed-product warehouses and operations with high picking frequencies.

Limitations to consider:

- Lower storage density compared to high-density alternatives

- Requires wider aisles, reducing floor space utilisation

- May not optimise facilities with high ceilings

Calculate cost per pallet position rather than just system price - selective racking's accessibility benefits often justify slightly higher per-pallet costs in Ireland.

Specify beam capacities matching your heaviest pallets with appropriate safety margins. Standard beam capacities typically range from approximately 900kg to 1,800kg per pair for lighter applications, with heavy-duty options available for heavier loads. Capacity depends on beam length, profile, material thickness and manufacturer specifications. Underspecified beams deflect dangerously under load. Overspecified systems waste budget on unnecessary structural capacity.

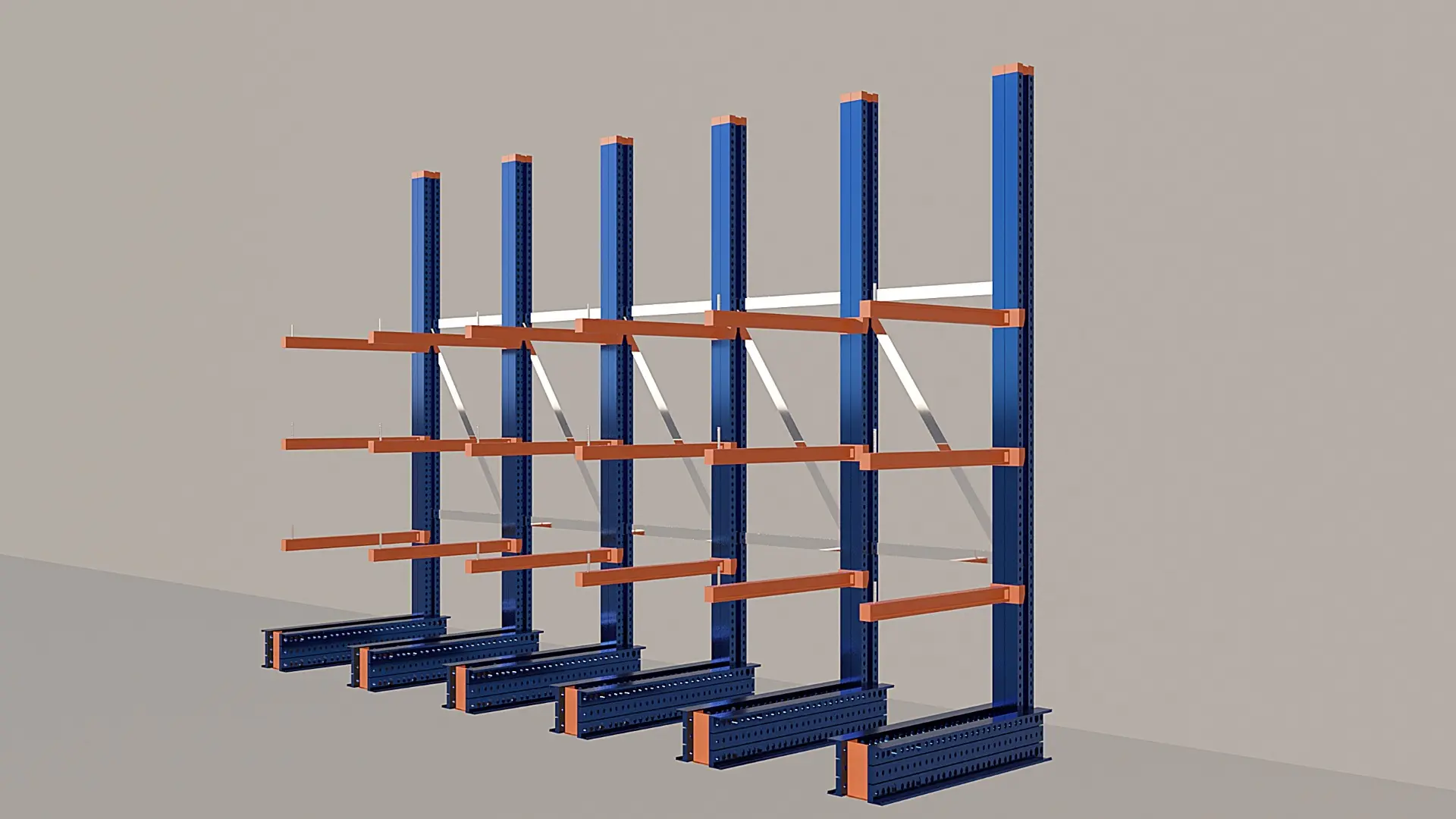

When Should You Choose Cantilever Racking for Your Warehouse?

Cantilever racking solves the storage challenge for long, bulky or irregularly shaped materials unsuitable for standard pallet configurations:

- Timber lengths

- Steel bars

- Pipes

- Furniture

- Carpet rolls

- Sheet materials

Cantilevered arms extending from vertical columns eliminate front obstructions, enabling horizontal loading and unloading. Single-sided configurations suit wall-mounted installations, maximising floor space. Double-sided systems provide access from both sides, ideal for central warehouse positioning.

Arm adjustability accommodates varying material lengths without system reconfiguration. Add or remove arms as inventory mix changes. This flexibility proves invaluable for builders' merchants, timber yards, and metal stockholders handling diverse product ranges.

Critical specifications:

- Arm length must exceed stored material dimensions by 100-150mm for safe placement

- Arm capacity depends on material weight and centre of gravity - longer arms support less weight than shorter configurations

- Floor anchoring requirements increase with system height and load

Cantilever systems typically cost 50-150% more than equivalent selective racking, but this premium proves justified for materials that simply cannot be stored conventionally. Alternative storage methods - floor stacking or custom fabricated racks - often cost more long-term through space wastage and handling inefficiency.

What is Drive-In Racking and How Does It Maximise Storage Density?

Drive-in racking maximises storage density by eliminating aisles between rack rows. Forklifts drive directly into rack structures, depositing pallets on rails. This configuration suits operations storing large quantities of identical products: beverage distributors, food wholesalers and cold storage facilities where space costs justify reduced accessibility.

Operational characteristics:

- Last-in, first-out (LIFO) inventory management

- Storage depths from 2 to 10 pallets

- Reduced forklift aisle requirements

- Ideal for slow-moving or bulk storage

- Typically 60-85% more storage capacity than selective systems in equivalent floor space

Important considerations:

Slower picking speeds compared to selective systems

- Reduced stock rotation capability

- Higher risk of rack damage from forklift impacts within confined spaces

- Requires specialised operator training

Drive-in suits operations where high-volume, low-variety storage outweighs picking speed requirements.

Specify rails and support brackets carefully. Guide rails protect upright frames from forklift contact. Rail spacing must match pallet widths precisely - loose pallets shift dangerously, tight fits prevent smooth placement. Budget for higher ongoing maintenance as confined space operations increase minor damage frequency.

When is Longspan Shelving the Best Storage Solution?

Longspan shelving bridges the gap between light-duty shelving and heavy pallet racking, accommodating hand-loaded items unsuitable for palletisation:

- Boxed goods

- Automotive parts

- Electronics

- Archived materials

Timber or steel shelves typically support 300-600kg per level, significantly exceeding light-duty shelving while remaining accessible without forklifts. Screwless assembly enables quick installation - starter bays erect in 10-15 minutes, extender bays connect seamlessly, expanding capacity incrementally.

Ideal applications:

- Pick faces for e-commerce operations

- Spare parts storage in manufacturing

- Archive systems for document retention

- Retail stockrooms requiring flexible configuration

- Mixed storage combining palletised goods with smaller items

Longspan systems integrate easily with pallet racking, creating comprehensive warehouse storage solutions. Position longspan picking faces adjacent to pallet reserve storage, enabling efficient restocking without excessive travel distances. This combination optimises both storage density and operational efficiency.

Configure shelving heights matching stored item dimensions. Wasted vertical space between shelves reduces system efficiency. Adjust shelf levels as inventory changes rather than accepting suboptimal configurations.

How Does Narrow Aisle Racking Increase Storage Capacity?

Narrow aisle systems reduce aisle widths from standard 3,000mm to approximately 1,600-1,800mm, significantly increasing pallet positions within existing footprints. This configuration requires specialist very narrow aisle (VNA) forklifts or guided wire systems, ensuring precision navigation.

Forklift Aisle Width Requirements

| Forklift Type | Typical Aisle Width | Storage Density | Best For |

|---|---|---|---|

| Counterbalance | 3,000-3,400mm | Standard | General warehouse use |

| Reach Truck | 2,700-3,000mm | Medium-High | Mixed operations |

| VNA (Very Narrow Aisle) | 1,600-1,800mm | Very High | High-ceiling facilities |

Advantages:

- Typically 40-50% more storage positions compared to wide aisle selective racking

- Efficient use of expensive warehouse space

- Maintains selective access to all pallets

High-ceiling facilities benefit most - the greater your racking height, the more valuable floor space becomes for warehouse optimisation.

Investment requirements:

- VNA forklifts typically cost €45,000-€90,000, substantially more than standard counterbalance machines

- Wire guidance systems, floor tolerances and operator training add costs

Calculate payback periods considering both equipment investment and space value

Narrow aisle suits established operations with stable product ranges, justifying specialist equipment investment. Growing businesses may find wide aisle systems more adaptable despite lower storage density.

What is Mobile Racking and How Much Space Can It Save?

Performance characteristics:

- Typically 80-100% capacity increase compared to static selective racking

- Full accessibility to every pallet position

Slower access times as aisles must be created before retrieval

Significant initial investment

Mobile systems excel in cold storage facilities where building costs can exceed €1,500 per square metre, making space optimisation financially imperative.

Consider mobile racking when:

- Floor space costs dominate operational expenses

- Inventory access frequency permits aisle creation delays

- Forklift operators can work efficiently within created aisles

- Floor construction supports substantial system weight (mobile bases, racking, and stored inventory)

Installation requires level floors within 3mm tolerance across the entire installation area. Floor preparation costs substantially impact total project budgets. Factor maintenance contracts for motorised carriage systems, ensuring reliable operation.

How Does Push-Back Racking Work and When Should You Use It?

Push-back systems use nested carts on inclined rails, enabling pallet storage 2-6 deep whilst maintaining better selectivity than drive-in configurations. Loading a new pallet pushes existing pallets backwards.

Retrieval brings forward pallets automatically through gravity.

This semi-LIFO system suits operations storing multiple pallets of the same SKU without requiring strict FIFO rotation: non-perishable goods, manufacturing components, and slow-moving stock where exact rotation matters less than space efficiency.

Selection criteria: Push-back works when:

- Storing 2-6 pallets per SKU

- Space efficiency outweighs perfect stock rotation

- Forklift operators can work efficiently with loading/retrieval patterns

- Budget permits higher initial cost versus drive-in alternatives

Specify cart systems carefully. Wheel-based designs require ongoing maintenance; roller systems demand precise installation but prove more reliable long-term. Consider the total cost of ownership rather than just the purchase price.

Pallet Racking Systems Comparison

| Racking Type | Storage Density | Accessibility | FIFO/LIFO | Best For | Relative Cost |

|---|---|---|---|---|---|

| Selective | Low-Medium | Direct access to all | FIFO | Diverse SKUs, high picking | € - €€ |

| Drive-In | High | LIFO only | LIFO | Identical products, bulk | €€ - €€€ |

| Cantilever | Medium | Direct access | FIFO | Long/bulky items | €€€ - €€€€ |

| Narrow Aisle | Medium-High | Direct access to all | FIFO | High-ceiling facilities | €€€€ |

| Mobile | Very High | Selective but slower | FIFO | Cold storage, expensive space | €€€€€ |

| Push-Back | High | Semi-selective | Semi-LIFO | Multiple pallets per SKU | €€€ |

| Longspan | Low-Medium | Direct hand access | FIFO | Hand-loaded items | € - €€ |

Note: Costs vary based on specifications, quantity, and supplier. Contact RackZone for specific pricing.

What Essential Accessories Do You Need for Pallet Racking?

Wire mesh decking prevents pallet collapse through beams, protects inventory below, and improves fire safety by allowing sprinkler coverage. Budget approximately €25-50 per deck panel, depending on dimensions and load capacity.

Racking accessories, including:

- Corner protectors

- Upright guards

- Safety barriers

These protect structural components from forklift impacts. This protection proves significantly cheaper than frame repairs or replacement following damage.

Load capacity signage on every bay prevents overloading, creating structural failures. Clear labelling ensures operators understand weight limits before placing pallets, maintaining safety margins throughout the system's lifespan.

Column protectors absorb forklift impacts that would otherwise damage load-bearing uprights. Position guards at vulnerable points: aisle ends, corners and high-traffic areas where minor contact incidents occur frequently.

What Should You Consider During Pallet Racking Installation?

Professional installation ensures structural integrity, HSA compliance, and optimal performance. DIY installation risks:

- Misalignment, creating stability issues

- Inadequate anchoring, compromising safety

- Incorrect component assembly, reducing load capacity

Verify installer credentials:

Relevant experience

- Insurance coverage

- Health and safety compliance

- References from similar projects

Floor condition critically affects racking performance. Inspect for:

Adequate load-bearing capacity

- Levelness within acceptable tolerances

- Crack-free concrete without deterioration

- Proper drainage preventing moisture accumulation

Address floor issues before installation rather than discovering problems afterwards.

Schedule installations to minimise operational disruption. Phased approaches maintain partial warehouse functionality during installation. Coordinate carefully with ongoing operations, avoiding conflicts between installation crews and warehouse staff.

How Do You Select the Right Pallet Racking Supplier?

Compare suppliers systematically beyond just pricing. Evaluate:

- Product quality and specifications

- Installation capabilities and scheduling

- Warranty terms and duration

- Spare parts availability

- Technical support responsiveness

- Company stability, ensuring long-term support

Request detailed quotations specifying:

- Exact components included

- Installation scope and exclusions

- Project timeline

- Payment terms

- Warranty coverage

Vague quotations create disputes during installation or afterwards when issues arise.

Verify compatibility with existing equipment. Beam styles, upright profiles and connection systems vary between manufacturers. Mixing incompatible components creates safety risks and operational problems.

Consider the total cost of ownership:

- Initial purchase

- Installation expenses

- Ongoing maintenance

- Operational efficiency

- System lifespan

- Adaptation costs for future changes

Cheapest upfront options often prove expensive long-term through higher maintenance, shorter lifespan, or operational inefficiency.

How Can You Future-Proof Your Pallet Racking Investment?

Design systems accommodating predictable growth and adaptation. Modular configurations enable capacity expansion without complete reconfiguration. Standardised components facilitate repair and modification using readily available parts.

Leave expansion space in initial layouts. Filling every available square metre prevents future growth within existing facilities. Reserve approximately 15-20% capacity for expansion, enabling organic growth without relocation.

Document your installation thoroughly:

- Layout drawings

- Load capacity specifications

- Component details

- Installation dates

- Maintenance records

Comprehensive documentation facilitates future modifications, ensures proper use and protects liability during inspections.

Review racking performance annually. Monitor:

- Damage incidents and patterns

- Capacity utilisation

- Operational efficiency

- Emerging needs

Proactive assessment identifies issues before they become costly problems, enabling timely adaptations to support changing requirements.

Partner with Ireland's Racking Specialists

Effective racking selection requires balancing multiple factors: storage requirements, access needs, space constraints, budget parameters, and operational workflows. Professional guidance ensures optimal warehouse storage solutions matching your specific situation rather than generic recommendations.

RackZone supplies comprehensive pallet racking solutions throughout Ireland. Our industrial shelving and warehouse shelving complement pallet systems, creating integrated storage addressing all your requirements.

As Ireland's sole Kimer distributor, we provide European-manufactured systems backed by 50+ years of engineering expertise. Our technical team conducts thorough site assessments, recommends optimal configurations, and manages professional installations, ensuring HSA compliance and efficient operations.

With next-business-day delivery across Ireland when you order before 3 pm, projects progress quickly. Browse our complete storage solutions or contact our specialists for personalised guidance. Call +353 (0)90 9673261 to discuss your warehouse requirements and discover how proper racking selection creates efficient, scalable storage supporting your business growth.

Value Shelving

Value Shelving  Warehouse Shelving

Warehouse Shelving Industrial Shelving

Industrial Shelving Garage Shelving

Garage Shelving Metal Shelving

Metal Shelving  Plastic Shelving

Plastic Shelving HORECA

HORECA Galvanised Shelving

Galvanised Shelving

Industrial Workbench

Industrial Workbench  Value Workbench

Value Workbench  Modular Workstations

Modular Workstations

Matting

Matting  Metal Lockers & Benches

Metal Lockers & Benches Office

Office  Slatwall

Slatwall  Cabinets

Cabinets Plastic Lockers

Plastic Lockers Lean Products

Lean Products Mobile Steps

Mobile Steps Wall-Zone

Wall-Zone

Longspan Racking

Longspan Racking  Cantilever Racking

Cantilever Racking  Industrial Pallet Racking

Industrial Pallet Racking Wire Mesh Decking

Wire Mesh Decking Tyre Racking

Tyre Racking Vertical Storage

Vertical Storage Racking Accessories

Racking Accessories Up & Over Gates

Up & Over Gates

Containers & Boxes

Containers & Boxes  Louvre Panels

Louvre Panels Crystal Box Systems

Crystal Box Systems Parts Bins

Parts Bins  Euro Containers

Euro Containers Visible Storage Boxes

Visible Storage Boxes  Foldable Crates

Foldable Crates

Shelf Bin

Shelf Bin Tool Organiser

Tool Organiser

Waste Management

Waste Management Cabinets

Cabinets Chemical & CoSHH Cabinets

Chemical & CoSHH Cabinets  Hex Lighting

Hex Lighting Packaging

Packaging

Platform Trolleys

Platform Trolleys  Hand Trucks

Hand Trucks  Pallet Trucks

Pallet Trucks  Plastic Pallets

Plastic Pallets