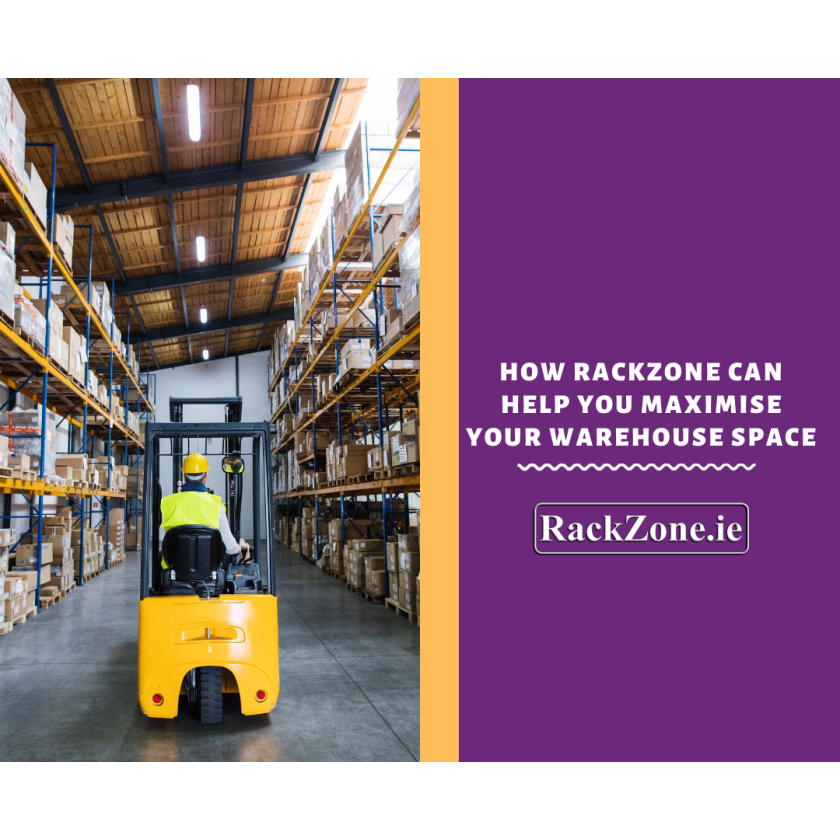

How RackZone can help you Maximise your Warehouse Space

Key Takeaways:

- Vertical space use through pallet racking can double or triple storage capacity.

- Strategic consolidation and organisation prevents wasted floor space.

- Proper pallet management and designated collection zones recover premium storage areas.

- Specialised equipment like narrow aisle forklifts can increase density by 40-50%

- Mezzanine floors can double usable space within existing building envelopes.

- Different racking types should match specific inventory profiles.

- Systematic small parts organisation reclaims valuable floor space.

Running out of warehouse space is one of the most frustrating operational challenges you'll face. Growth spurts, bulk purchasing, seasonal peaks or declining sales can all compress your available floor space faster than you'd expect. Expansion isn't always viable given property costs and availability constraints. The solution is optimising what you've already got, and there are proven strategies to achieve significant capacity increases without moving premises.

How Can You Use Vertical Space to Maximise Warehouse Capacity?

Your warehouse's height remains the most underutilised asset in most facilities. You've paid for the cubic volume, so use it. Industrial pallet racking systems let you stack inventory vertically, transforming wasted ceiling clearance into productive storage capacity. Standard warehouse heights of 6-8 metres can accommodate multiple rack levels, potentially doubling or tripling your storage density compared to floor-level only arrangements.

When configuring vertical storage, don't just consider height. Depth matters equally. Longspan shelving units come in depths ranging from 400mm to 800mm, allowing you to maximise both dimensions based on your product profiles. You can also reclaim space by narrowing aisle widths between racking runs, provided your material handling equipment can operate safely. Each 100mm reduction in aisle width across a 30-metre run recovers 3 square metres of floor space.

Why Is Organisation and Consolidation Critical for Warehouse Space?

Disorganised warehouses waste spectacular amounts of space through inefficient product placement and poor inventory discipline. Strategic stock placement keeps related items together, reduces picking time and prevents the gradual entropy that consumes usable floor area. Storage containers with lids and shelf bins condense loose items into stackable, locatable units that integrate with your existing shelving infrastructure.

Consolidation discipline makes enormous differences. Those three partially filled pallets scattered across different locations? Merge them onto one pallet and you've freed two pallet positions. It sounds obvious, but it gets overlooked during busy periods. Implement a daily consolidation sweep where staff merge partially depleted stock. The recovered space compounds quickly, particularly in high-throughput operations.

How Does Proper Pallet Management Increase Storage Efficiency?

Pallet management directly impacts your spatial efficiency. Empty pallets accumulate like sediment, gradually reducing your effective storage area.

Key pallet management strategies include:

- Establish designated pallet collection zones away from primary storage areas

- Consolidate partial pallets systematically rather than letting them occupy premium locations

- Implement daily pallet reviews to identify consolidation opportunities

- Create clear protocols for empty pallet handling

Consider your pallet configuration options carefully. Adjustable pallet racking gives you the flexibility to modify beam heights without structural changes, letting you accommodate varying pallet sizes whilst maintaining density. For operations storing identical products in high volumes, drive-in configurations can increase capacity by up to 85% compared to selective arrangements by eliminating multiple aisle requirements.

What Equipment Upgrades Maximise Warehouse Storage Density?

Equipment selection profoundly affects space utilisation. Narrow aisle forklifts enable narrow aisle racking configurations that dramatically increase storage density by reducing aisle widths from 3.6 metres to as little as 1.8 metres. The increased rack density often justifies the specialised handling equipment investment within 18-24 months through recovered floor space.

Key equipment considerations for space maximisation:

Narrow aisle forklifts: Reduce aisle widths from 3.6m to 1.8m, potentially increasing storage positions by 40-50%

Wire mesh decking: Prevents small items from falling through beam levels and supports non-palletised goods

Pallet inverters and exchangers: Handle damaged pallets efficiently, reducing space consumed by segregated damaged goods

Racking accessories: Expand storage versatility within existing footprints

Racking accessories like wire mesh decking prevent small items from falling through beam levels and support non-palletised goods, expanding what you can store within the same footprint.

When Should You Consider Installing a Mezzanine Floor?

Mezzanine floors represent a permanent but highly effective solution for facilities with adequate ceiling height and structural capacity. You're essentially creating a second floor within your existing building envelope, potentially doubling usable space without expanding your property footprint. Building layout and load-bearing capacity determine feasibility, so structural assessment precedes any installation.

Mezzanines support functions that don't require high-bay storage: picking operations, packing stations, quality control areas or even administrative offices. You maintain ground-level operations for heavy goods and palletised inventory, using the upper level for lighter activities. Warehouse shelving units work excellently on mezzanine levels, providing organised storage for hand-picked items without requiring forklift access.

The capital investment is substantial, but ROI often arrives within 2-3 years through increased capacity and operational efficiency gains. You're paying considerably less per square metre than acquiring additional property or relocating to larger premises.

Why Should You Use Different Racking Types for Different Products?

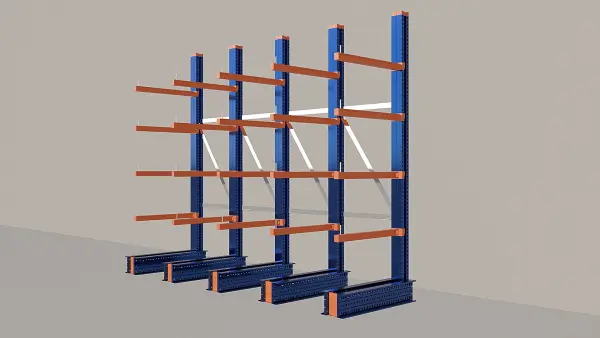

Different product types demand different storage solutions. Relying exclusively on standard pallet racking when you're storing long materials wastes enormous amounts of space. Cantilever racking efficiently stores timber, pipes, steel sections and other awkward-length items that don't suit conventional pallet configurations. The absence of front columns allows unrestricted load access and variable length accommodation.

For operations handling diverse inventory profiles, mixing racking types optimises overall density. Combine selective pallet racking for fast-moving, frequently accessed stock with higher-density drive-in systems for slower-moving bulk items. Vertical storage solutions maximise ceiling height for appropriate product categories. Match your storage infrastructure to your inventory characteristics rather than forcing everything into one system type.

Warehouse Racking System Comparison

| Racking Type | Best Application | Key Benefit |

|---|---|---|

| Selective Pallet Racking | Fast-moving stock requiring frequent access | Direct access to every pallet position |

| Drive-in Racking | High-volume storage of identical products | Up to 85% capacity increase vs selective racking |

| Cantilever Racking | Long, bulky or irregularly shaped materials | Unrestricted load access without front columns |

| Narrow Aisle Racking | Maximum density operations | 40-50% capacity increase through reduced aisle widths (1.8m vs 3.6m) |

| Longspan Shelving | Hand-picked items of varied sizes | Depths from 400mm to 800mm for flexible storage |

Table: Warehouse racking systems and their space optimisation benefits

How Can Small Parts Organisation Recover Warehouse Floor Space?

Small components and parts create spatial chaos if not managed properly. Parts bins and bin racks transform loose hardware into organised, visible storage that consumes minimal floor space. Wall-mounted systems reclaim vertical wall surfaces that otherwise contribute nothing to your storage capacity. Labelling ensures rapid location and retrieval, reducing the time staff spend searching for components.

Effective small parts storage solutions include:

- Wall-mounted bin racks that use vertical wall surfaces

- Labelled parts bins for rapid location and retrieval

- Tool organisers to prevent workbench sprawl

Shelf bins that integrate with existing shelving infrastructure

Tool organisers and small parts management systems prevent the gradual sprawl of loose items across workbenches and floor areas. Every square metre recovered from disorganised small parts storage can be redeployed to higher-value inventory storage.

Why Choose RackZone for Your Storage Solutions

Every warehouse faces unique operational requirements and spatial constraints. You need storage infrastructure that's properly specified for your inventory profiles, handling equipment and operational patterns. We supply cost-effective pallet racking systems, shelving solutions and storage organisation products backed by technical expertise and nationwide delivery across Ireland.

Order before 3pm for next-business-day delivery throughout Ireland. Contact us on +353 (0)90 9673261 or email info@rackzone.ie to discuss your warehouse space optimisation requirements.

Value Shelving

Value Shelving  Warehouse Shelving

Warehouse Shelving Industrial Shelving

Industrial Shelving Garage Shelving

Garage Shelving Metal Shelving

Metal Shelving  Plastic Shelving

Plastic Shelving HORECA

HORECA Galvanised Shelving

Galvanised Shelving

Industrial Workbench

Industrial Workbench  Value Workbench

Value Workbench  Modular Workstations

Modular Workstations

Matting

Matting  Metal Lockers & Benches

Metal Lockers & Benches Office

Office  Slatwall

Slatwall  Cabinets

Cabinets Plastic Lockers

Plastic Lockers Lean Products

Lean Products Mobile Steps

Mobile Steps Wall-Zone

Wall-Zone

Longspan Racking

Longspan Racking  Cantilever Racking

Cantilever Racking  Industrial Pallet Racking

Industrial Pallet Racking Wire Mesh Decking

Wire Mesh Decking Tyre Racking

Tyre Racking Vertical Storage

Vertical Storage Racking Accessories

Racking Accessories Up & Over Gates

Up & Over Gates

Containers & Boxes

Containers & Boxes  Louvre Panels

Louvre Panels Crystal Box Systems

Crystal Box Systems Parts Bins

Parts Bins  Euro Containers

Euro Containers Visible Storage Boxes

Visible Storage Boxes  Foldable Crates

Foldable Crates

Shelf Bin

Shelf Bin Tool Organiser

Tool Organiser

Waste Management

Waste Management Cabinets

Cabinets Chemical & CoSHH Cabinets

Chemical & CoSHH Cabinets  Hex Lighting

Hex Lighting Packaging

Packaging

Platform Trolleys

Platform Trolleys  Hand Trucks

Hand Trucks  Pallet Trucks

Pallet Trucks  Plastic Pallets

Plastic Pallets